by SITECH UK-Ireland | Mar 1, 2021 | Case Study

Ground Developments is a UK ground engineering contractor, offering a range of services, including earthworks and a range of ground improvement techniques for infrastructure, roads, housing, and commercial building construction. The company from Whitburn (halfway between Glasgow and Edinburgh) was founded in 1998 and has grown into a specialist company employing a 40–50-person crew and turning over some 18-20 million GBP. Working with Trimble technology, the company has seen a 40+% improvement in efficiency in production outputs over just four years.

Ground Developments was founded with a vision of bringing soil stabilisation to the UK, growing from a general civil contractor role into the role of a specialist in this field. But with rising amounts of work, the team had to spend a growing percentage of time on engineering, profiling, and trying to achieve grade. Realising that they were getting limited production from the machines, the directors became interested in Trimble machine control technology. And in 2011 they went out to see it in action.

They were so impressed that, as the first company in Scotland, they decided to invest in equipping the Ground Developments dozer fleet with Trimble solutions. Back then these were used mainly to support formation levelling. Working with Trimble and SITECH UK & Ireland over the years, the Ground Developments team now operates a fleet of Komatsu and Cat® equipment, equipped with Trimble Earthworks and Trimble GCS900 3D machine control technology. The office runs Trimble Business Center as the data heart of the operation.

Wayne Barr is the company’s production director and is a driving force behind the adoption of Trimble technology company-wide. “We are now using Trimble machine control on our entire excavator and dozer fleet, and I just love it,” he says. “Over the years we have developed a strong relationship with Trimble, and we’ve even beta tested some of the latest technology. It has helped us make tremendous progress rooting out inefficiency and gaining productivity working with real time data, exchanged between the office and the machines.”

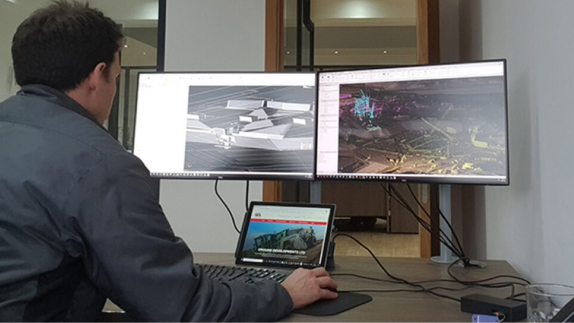

“One of our directors, Julius Newman, is leading the design efforts, and we’ve been really lucky to have such an experienced designer with survey engineering experience on board. Because the surface models are the basis for all that we’re doing in the field.” He turns the designs from the client ― usually 2D drawings ― into surface models using Trimble Business Center. We generate task specific designs from those models and wirelessly push those out via Trimble WorksManager to the machines in the field.

“With Trimble WorksOS we can keep track of where the machines are, the progress they’re making and the day-to-day cut, fill, volume, and compaction data, all highly accurately. In earlier days you would sometimes be looking at week-old machine data in the office.” It is the interaction between the machines and the office, that helps Ground Developments win business. A lot of new business, and a lot of repeat business. Customers value the level of accuracy the contractor can provide, the small tolerances their machines can operate to and the level of detail in reporting.

Accuracy is particularly important on soil improvement projects; the type of work Ground Developments specialises in. A compiler operator enhances the soil by injecting grout at a 5-meter depth. Deep soil mixing is typically used to improve the strength and stiffness characteristics of soft to very soft formation soils. “We divide the area up into a 3×3-meter grid and inject every cell with a fixed amount of grout based on the time the injection process runs,” Barr explains. “Obviously the operator can’t see the grout go in, but in this case the machine data coming from the injector boom extension ― that is programmed as a bucket attachment ― provides accurate insights by telling the Trimble system the grout was injected at the right location. Another computer measures the exact right amount to meet the requirements. So, the geotechnical team can then report and validate that the treated area has bottomed out to a firm formation, based on the machine data. In the future we will take it one step further and feed the data back into the 3D model so we can see that develop in real-time.”

For Ground Developments, fully embracing the Connected Construction concept has meant so much more than just getting the most out of the machines. “We’re optimising models in the office, pushing these out to the machines on the fly, recording information on the work that is being performed, and feeding all that back to the office for production reporting and, if necessary, model rework,” Barr comments. “We have gone full circle. By keeping projects on track, thanks to the Trimble technology, we can take new ones on in the knowledge that we’ll finish on time for the next one. It has truly changed our entire operation.”